硫磺在橡胶输送带中有哪些作用?

白色输送带生产厂家报导硫磺在橡胶制品工艺中的作用都有哪些?硫磺是自然界中比较常见的一种矿物质。一则具有很高的药用价值,二则在橡胶中的应用也是非常广泛的。19世纪的时候,橡胶只是用来做防水材料,原因是由于橡胶不耐热,在高温状态下容易融化和变软。

What are the functions of sulfur in rubber products reported by white conveyor belt manufacturers? Sulfur is a common mineral in nature. One is of high medicinal value, the other is widely used in rubber. In the 19th century, rubber was only used as a waterproof material because it was not heat-resistant and easy to melt and soften at high temperatures.

白色输送带生产厂家报导:1839年,固特异把氧化铅、橡胶、硫化这三种化合物混合在一起的时候,放在高温下并不容易分解。经过长时间的研发和改良,橡胶已经不会在100摄氏度以下的温度分解了。现在越来越多的耐热橡胶产品已经研发出来,加入顺丁橡胶、丁苯橡胶的产品可以耐热120~150摄氏度,而加入三元乙丙的橡胶则可以耐热180摄氏度。这也是橡胶工业的一个重大的进步。

The white conveyor belt manufacturer reported that when Goodyear mixed lead oxide, rubber and vulcanization together in 1839, it was not easy to decompose at high temperature. After a long time of development and improvement, rubber will not decompose below 100 ℃. Now more and more heat-resistant rubber products have been developed. The products with cis-1,4-polybutadiene rubber and styrene butadiene rubber can be heat-resistant at 120-150 ℃, while the rubber with EPDM can be heat-resistant at 180 ℃. This is also a major progress in the rubber industry.

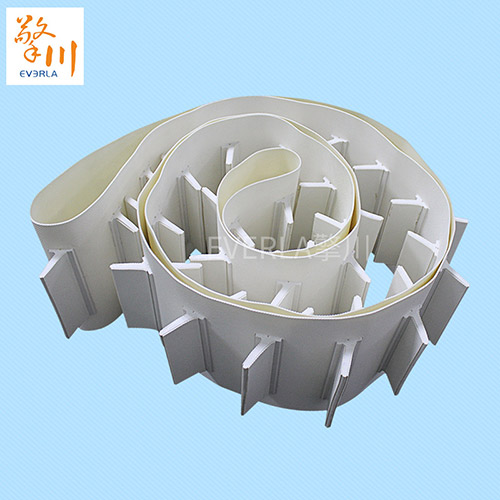

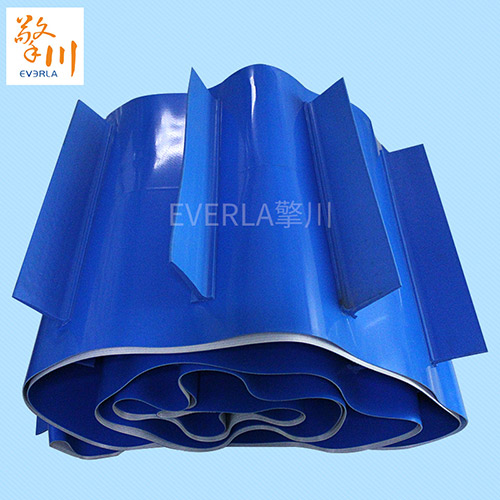

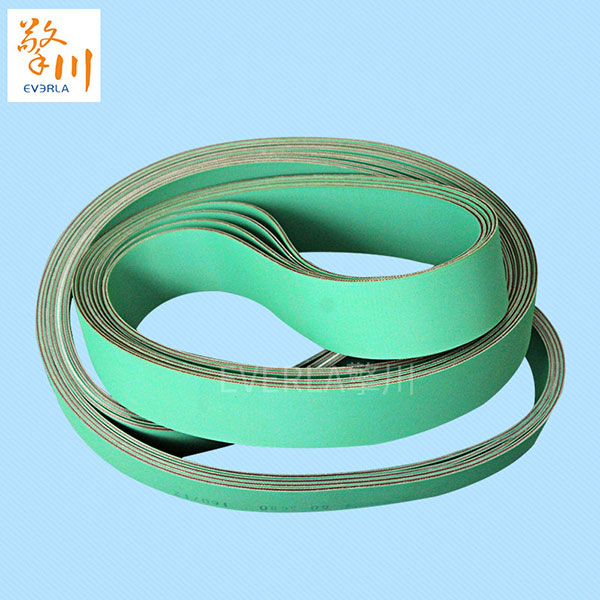

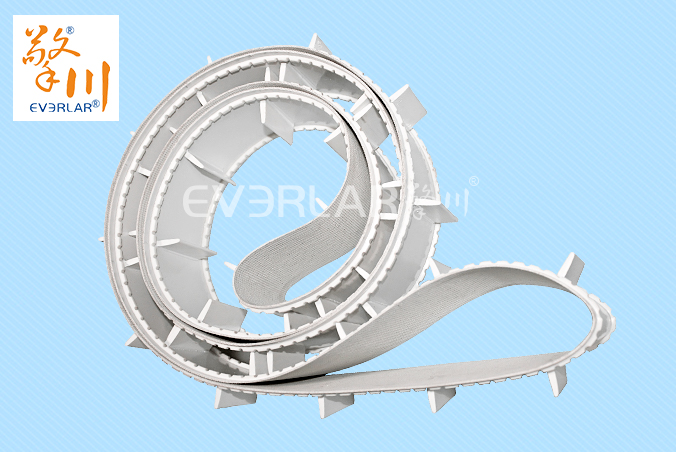

白色输送带

White conveyor belt

白色输送带厂家报导硫化的分类:

Classification of vulcanization reported by white conveyor belt manufacturer:

1. 硫磺粉:将块状的产品磨成粉状的,这种是应用广泛的一种,能均匀的分散在橡胶制品中,使他的性能充分挥发出来。

1. Sulfur powder: grinding the lumpy product into powder, which is widely used. It can be evenly dispersed in rubber products to fully volatilize its performance.

2. 不溶性硫磺:这种硫磺加工工艺比价麻烦,所以价格也是比较高,质地优良,主要用在高档的橡胶制品中,生产出来的橡胶产品外表美观,质量好。

2. Insoluble sulfur: the sulfur processing technology is troublesome compared with the price, so the price is relatively high and the quality is good. It is mainly used in high-grade rubber products. The rubber products produced are beautiful in appearance and good in quality.

3.胶体硫化:是一种乳状产品,主要是和乳胶产品一起使用。

3. Colloidal vulcanization: it is a kind of emulsion product, mainly used with latex products.

橡胶产品之前应用没有那么广泛,性能也不完善,有了硫磺这一配合剤后,性能更加完善,并且成为应用更加广泛的高分子的材料

Rubber products have not been widely used before, and their properties are not perfect. With the sulfur compound, the performance is more perfect, and it has become a more widely used polymer material

本文由切菜机输送带整理发布,您是不是对这些内容有所了解了呢?更多的内容请点击:http://www.everla.com 我们会有更多精彩内容等你查看。

This article is organized and released by the conveyor belt of the vegetable cutter. Do you know anything about these contents? For more information, please click: http://www.everla.com We'll have a lot more to see.

以上就是擎川EVERLA给大家分享的“ 硫磺在橡胶输送带中有哪些作用?”相关信息,希望通过介绍,能对大家有所帮助,擎川输送带厂家15年专注于食品输送带、PVC输送带、PU输送带、PU同步带、特氟龙输送带、尼龙片基带研制生产,为食品、医药、日化领域提供一站式输送带解决方案。如果您有输送带的采购需求,欢迎来电咨询400-9688-278